Digital Jacquard Looms Debut in Winter 2023

The Penny W. Stamps School of Art & Design recently purchased two Thread Controller 2 (TC2) digital jacquard looms, which are state-of-the-art, computer-assisted machines used for hand weaving.

Stamps faculty Annica Cuppetelli and Rebekah Modrak first advocated for the additions. They pursued the technology with a vision to ensure that all Stamps students – even those with no previous experience, could try other genres of artmaking and production.

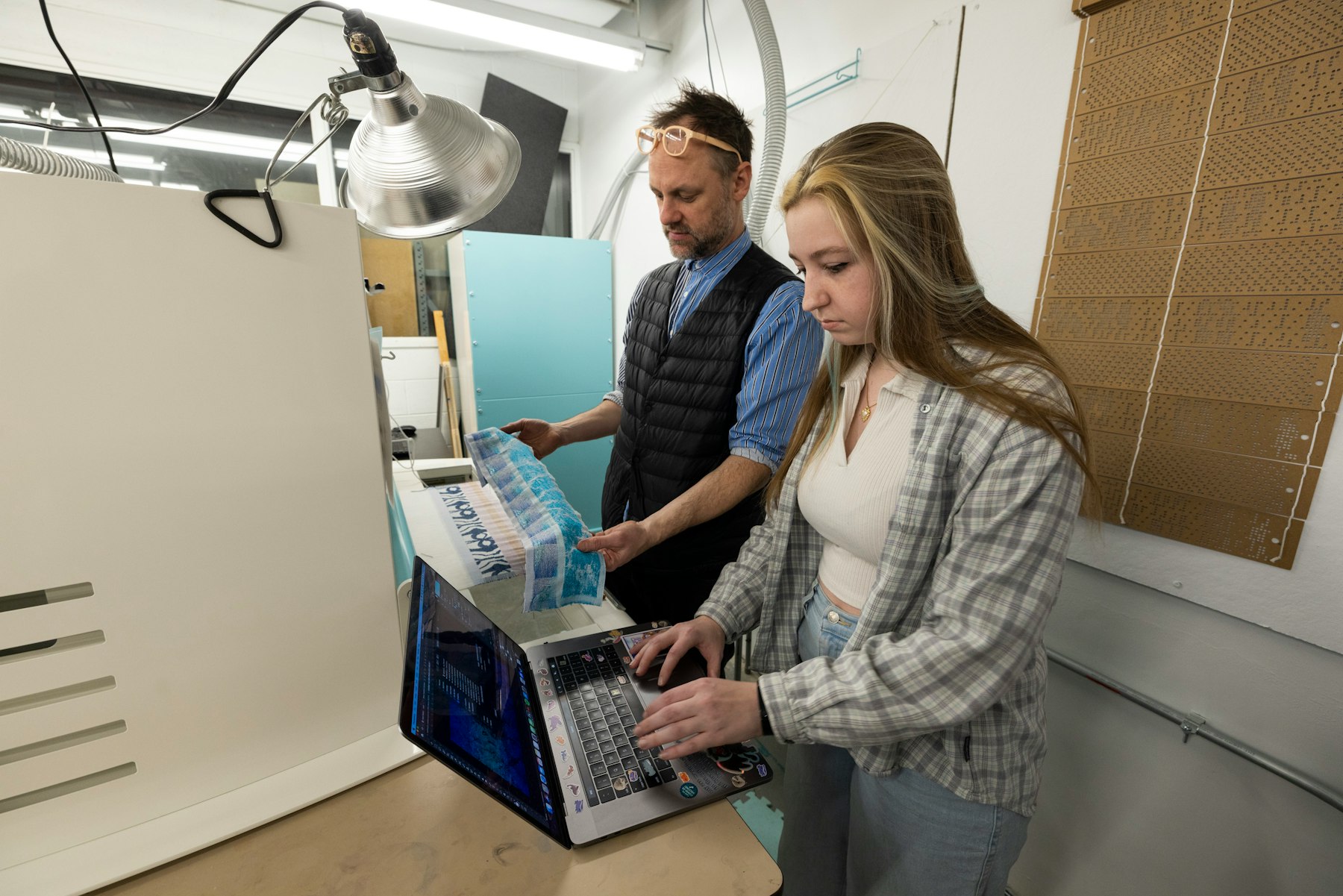

The looms were launched within class instruction this Winter 2023 semester. Textile Weaving: Analog to Digital, taught by instructor Michael Andrews, intertwines this technology into the Stamps curriculum.

Weaving Experience for All

Andrews, who previously taught jacquard weaving and other forms of digital output at the School of the Art Institute of Chicago, says that the jacquard looms allow students with no weaving experience to participate. Students can use familiar programs like Photoshop and Procreate to weave.

“We live in a world of pictures. Students are comfortable thinking through and with images. This is exactly why it was decided that half of the class should be open to students with no weaving experience,” Andrews said. “There is often a student who has never woven before that really gets into the intricacies of woven structure and image making. It’s a great form for someone who likes to tinker and test.”

Andrews also recalls how the digital jacquard looms apply to multiple areas of art and design, making them ideal for the vast curriculum at Stamps.

“I’m teaching this class in a way that does not demand an allegiance to any particular category or design,” Andrews said. “Creating cloth means there are multiple options for display or use. A piece that a student weaves on the loom could be in conversation with painting, photography, textile design, architecture, digital media, or fashion.”

The class is translating digital files into woven materials throughout the semester.

Uplifting the Institution

Student Hava Reeves Liebowitz was eager to enroll in the course. She says the advanced technology indicates that fiber arts are elevated at Stamps.

“In many institutions where fiber arts are appreciated and uplifted, a jacquard loom is one of the tools available to students, so it is really exciting that we have it here at Stamps,” Liebowitz said. “Additionally, a lot of fiber artists that I look up to have used the jacquard loom at some point in their career, so it’s cool that I have access to it.”

Andrews says the technology will give Stamps students a competitive edge.

“Training Stamps students on these tools will help make them competitive applicants for roles within fine art and design as well as for advanced study at the graduate level,” Andrews said.

The Future of Weaving at Stamps

According to Fiber & 2D Foundations studio coordinator Kit Parks, the looms will allow artists to manipulate each thread individually using computerized controls, leading to more detailed and realistic images. An image created or edited in Photoshop can be sent directly to the loom for production.

“Because the TC2s enable the creation of highly detailed images, I expect we’ll see more pieces that highlight pictorial elements,” Parks said.“These looms also offer more efficiency than a traditional floor loom, so we may see larger works as well.”

While traditional analog weaving is a practice spanning thousands of years ago and used across cultures, Parks says that innovation is a major part of the weaving mindset. This idea will be covered in Textile Weaving: Analog to Digital.

“It’s the nature of the weaver to innovate and constantly look for ways to optimize materials and time while pushing the bounds of what is possible in a woven structure,” Parks said. “We are incredibly privileged to have this equipment in our school.”

To see students’ work at Stamps, follow @umstamps on social media.

Story by Katelyn Stuck.